Over the years I fielded hundreds of calls from customers and students asking if I think it’s time for them to get an automatic press. After all, “they are just so busy that they can’t keep up with all the orders – and of course they are making pretty good money now and with an automatic they could do great!”

These calls are a little scary because I know that in most case the caller hasn’t really thought through the ramifications of getting into automatic equipment. Although I am a great advocate of business growth, I also know that purchasing an automatic press that will print 40 to 60 dozen prints- per-hour is a major decision that should not be taken lightly.

In this short article I would like to explore the major considerations of moving up to an automatic press and the impact it will have on your business AND your bottom line. While this article may dwell on the negative (just to give you food for thought) it also has some very positive ideas including the answer you want to hear – YES if you think it is time and you have done your homework then get that automatic!

ARE YOUR REASONS TO AUTOMATE VALID?

Why do you want an automatic press? I know…it’s to get production out faster…but is that the real reason?

Do you have a major customer who has promised those large orders if you could just handle his needs? Loyalty is a funny thing. If the price or mood of the customer isn’t right you will find yourself stuck with that large monthly payment with the promises of big orders snatched away overnight.

Do you have hundreds of small orders? Even though many shops put those 4 dozen orders on the auto, I think you need steady sizable orders to really keep the press running.

Does your ego tell you this is the move to big time? Do you day- dream at trade shows about how great it would be to print all of those shirts every hour?

The real REASON to automate is that you have built a solid business of many steady customers who give you those 300 – 1000+ shirt orders on a regular basis. If you have the groundwork in place then I say let’s move on and examine the things you don’t think about and maybe the things the salespeople don’t tell you.

HOW TO HANDLE TODAY’S PRODUCTION

First, you need to look at what is happening today. What ways can you handle the crunch of orders today. Getting an automatic isn’t going to happen overnight. In fact, from the time you place the order, arrange financing, wait for shipping, install the equipment and get your people trained, it could be three months or more down the road before you ever print your first automatic shirt! And, in a depressed economic climate you really need to think this through.

Maybe the short term is to increase production now while you plan your major purchase. Do you do a lot of unnecessary flash curing because of poor artwork, bad habits, wrong mesh or slow help? It could be that you really aren’t ready for the auto, but are in need of a fundamental technique tuneup instead.

You could probably increase production by 50% with less flash curing through proper artwork preparation, correct ink viscosity, screen mesh and printing techniques. You could pick-up another 50% with TEAM PRINTING. By investing in an ALL HEADS DOWN manual press where more than one person can print at a time you could go from 7 to 10 dozen 4-color prints per hour (with 1 printer and 1 helper) to 12 to 15 dozen 4-color prints per hour (with 2 printers and 1 helper)! And of course the profits per hour go up because you are getting a lot more prints per hour with a minimal increase in wages!

How about contracting some of the overflow work out? At least you can start to handle more work and will be able to see how steady this work really is. If you are going to send work out though, make sure that you are in total control of the artwork and screens. There should be a clear understanding as to ownership of artwork, film positives, screens AND the soliciting of your customers direct.

IF YOU AUTOMATE WHO WILL RUN IT?

Sure, you will just promote one of you printers to be in charge of this new toy. Don’t be surprised when the employees are not overjoyed at this expensive hunk of metal. How would you feel when the boss says the shop will now be able to get all the day’s work done by noon. Sounds like maybe someone will have to go. Or what if you tell the employees that production will now go from 500 pieces per day to 4,000 pieces per day!

Better yet, what will you do with the auto screams through a months worth of work in a week or less. Do you lay people off for three weeks?

You will need to find the person who likes to work with machinery and a wrench! Someone will need to be the designated “fixer.” You’re not going to call the factory every time something goes down.

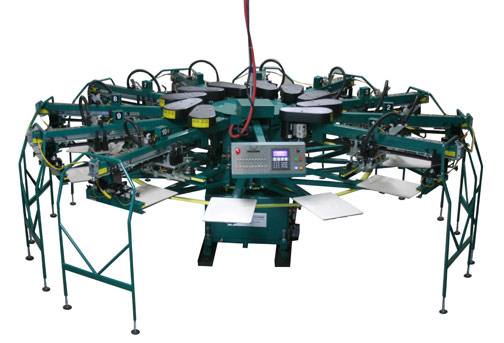

TYPES OF EQUIPMENT

There are as many opinions of what automatic to buy as there are automatic manufacturers. Decide what you need first.

Are you looking for a 6, 8, 10 color or more? You can get a small format six or eight color for $25,000 to $45,000. If you are looking at a mid-sized 8 to 14 color, expect to spend $55,000 to $100,000. And, if you really want to go crazy and get a large format or belt printer for all-over prints, you need a rich uncle.

For many of you the question is do I buy a six color or eight color. Frankly, even though there are some very nice six-color presses, for some of the nice dark shirts being done, eight-colors is a minimum and for the extra $7,000 to $10,000 (approx) to go from a six to an eight, I say do it.

Also, an eight color automatic press is not really eight colors if you start to flash cure. When you print manually, flash curing does not take up a print head. On an automatic, a flash unit generally replaces the print head AND it may be necessary to allow the next station to be the cool down station for thicker inks on dark shirts! This means that great eight color is really a six color. (Note: there are automatic presses that allows you to flash AND print at the same station – with a sacrifice in production speed.)

WHAT ARE THE HIDDEN COSTS?

This is where things really get out of whack. You had been hearing an automatic can be purchased for less than $30,000! You look at the lease payment and figure the press can easily make the $1,500 to $2,000 per month payment and still generate a profit. That $30,000 (on the low side) is just a start!

Freight and Set-up

The freight alone could be a few thousand dollars, not even counting the rigging to get the machinery off the truck and in the shop.

Generally the factory wants to send their man to install the press and you now have a fee for this, air-fare, housing and meals. Also, someone has to hook-up the electrical and of course you will generally need an air-compressor and we are not talking about the one you buy for $100. Plug in a few thousand for this.

If you are lucky you will have a large overhead door and be on the ground floor, but if not, how is the equipment going to get in the freight elevator or through the doorway?

A few years ago we installed an automatic press in our Arizona school (on loan from Tuf Products) and have painful memories of the extra expenses. After purchasing a 7-1/2 horse power compressor with chiller ($2,000); paying the expense of the installer and airfare ($1,500); paying the freight ($750); renting a 5,000 lb. forklift for one day ($200); hiring an electrician to hard wire the compressor, printer and flash unit ($400); and buying air hoses, fittings and assorted parts ($250)…you get the picture. And, this was for a small six-color press.

Spare Parts

The base price is kind of like buying a new car. There are always the extras. You’ll need different size pallets for kids shirts or piece goods. How about a flash-curing unit and maybe a safety package.

There are also spare parts packages. Certain parts are prone to break and it is better to accept that as a fact of life and buy the important small parts before you need them.

Training

Ideally you will be able to hire someone who has automatic experience. Don’t count on it though. Besides the calls we use to get for automatic equipment information, we got MORE CALLS from people looking for good production people who knew automatics. There is a real void in the job pool for this kind of help. We are in a growth business and good people are hard to find.

Many manufacturers offer some sort of on-site training or training at their schools. Don’t expect too much here though. There is only so much you can be taught in a few days. The school of a few hours on the press and a box of rag shirts are the real training ground. Unfortunately, these hidden costs generally are paid in CASH. You can’t lease freight, set-up, electrical, training, etc.

Will Your Existing Equipment Work?

Can your small 8’ dryer handle 50 dozen prints-per-hour? Not! You need to get serious about a larger dryer and of course we are now talking more power to run it along with the space.

Exposure Unit and Screens

The automatic screen sizes are generally 23″ x 31″ minimum. Can you fit these oversize screens on your existing unit? Worse yet – will your existing screens fit on the new press? Probably not! There will be a lot of nights of re-burning screens for the jobs you want to put on the automatic.

Manual Press

Will your manual equipment handle those oversize screens? If not – how are you going to proof and test jobs before you put them on the automatic? Maybe another oversize manual press should go on your shopping list too!

THINGS TO EXPECT AND DO

Screen making will need to be re-thought. Close pre-registration of screens is very important for faster set-up. Also more durable screens are important because of the constant squeegee pressure in the same spot on the screens. Screen breakdown is common. Maybe spare screens will be needed on long jobs to minimize down time if a screen falls apart.

You can easily go through CASES of spray adhesive. Investigate automatic spray systems or go to pallet tape.

Some jobs just won’t work on the automatic. Nylon jackets can be very difficult, along with shirts requiring lots of flashes. Problem jobs that need a little finesse are better done by hand.

Quality control will need to be a top priority. By the time you catch a problem like lint on a screen or a screen that has run dry of ink it could be 12 shirts later!

Don’t expect too much help from the manufacturer. This is not true of everyone, but you should be prepared to find the answers to your problems yourself.

FINANCING

Since we are talking a minimum of $25,000 to $50,000 for your new toys, be prepared to work on getting a lease – if you can in today’s market. It is much harder to get approved for leases over $25,000. And, in a depressed economy you may find financing non-existent. You can also expect at least 3 payments as the down payment, and to provide 3 years of tax returns, financial statements and even a request for a personal guarantee.

Another option is supplier financing. Depending on the mood of the market, this could be your ticket to getting what you want.

THE GOOD NEWS

After all the above negatives, there better be some positive reasons to do all this.

Of course you can expect much higher production. Although you won’t consistently get the high figures the manufacturers publish, you will get a lot more than you are use to! Rates of 35 to 50 dozen per hour on the average are common if you pay attention to all the variables you should be watching now – good art preparation, screen making, ink use and more.

The quality will also be very consistent from print to print. You have to rely on less manual feel and operator technique.

You will also be able to take jobs you never thought possible. Of course your everyday work will be done in a flash. What use to take two or three days will now take hours! This may take some getting use to. A friend of mine commented that he loves his automatics because he isn’t a very good planner. He can do jobs so quick that even if the shirts arrive late (because he forgot to order on time) he can still get orders out. In by 3:00 -out by 5:00 is his motto.

Your market will also expand. You will find yourself going after a different type of customer. Once word gets out that you have an automatic press customers will find you. You may even be tempted to go after contract printing just to make extra money.

In closing, take a hard look at the reasons for moving up to an automatic press. Can you afford it? Is there extra reserve money for the things you can’t finance? Does your business volume really warrant it or are you busy now because of that one large customer?

If you think the time is right, then go for it! I guarantee you you will never turn back. Once you get an automatic you’ll wonder what you did without it.

Good Luck